Up until 2012 I had not experienced any problems with my negatives apart from the problem of water marks. The amount of times prints had been ruined because I had missed one of those dam circles. Life went on, I slowly got the hang of checking for these marks and dust.

Around about the time I started to investigate other developers. Among my group of photographer friends a number of them were talking about PMK Pyro and how it produced super fine negatives with it's staining action. I was told it came in powder form and once made up would last for almost ever.

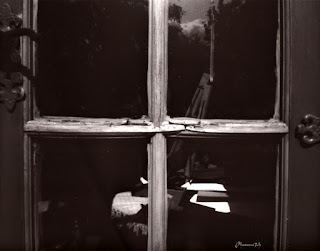

It became my main developer producing some wonderfully smooth toned negatives and some super smooth prints I was over the moon with the results. That is until a roll of FP4+ produced this mottled affect I was stumped to the cause. The next film I developed was clear of it and so it remained for years. Over time trying a number of different developers along the way without the affect.

Then all of a sudden three film in a row one FP4+ developed in RO9 and two rolls of Fomapan 100 one in RO9 the other Studional. So it had now't to do with the developer but something common to all three. At the time I traced it to contaminated developing tank and spirals with wetting agent and wrote an article on how I traced it. There will be a link to it at the end.

The up shot of it was I stopped using wetting agent completely leading to negatives that dry twice as fast and with no water marks. I have been using a soft wet leather to wipe the negatives dry with no ill affects for years. The mottling disappeared as well or did it?

Until recently it is back with a vengeance it has appeared on half a dozen rolls of Fomapan 100. All processed one after the other using HC 110 the difference this time is I know it is not the developer or wetting agent contamination. I was put out only in the sense of its unpredictability I have embraced the mottle as a creative tool and like the affect it has on the photographs produced.

The one bit of information missing so far is that all the affected rolls of film have been 120 format. I went to the film cupboard there was a new unopened pack of 10 Fomapan 100. I opened it and pulled out a roll. Took it out of it's rapper ready to load in the Bronica. What is this? It has the same white silky backing paper as Ilford? Slowly the cogs clanked round.I still had some from the pack I just processed, what's the best before date? 2018. it would seem you are more likely to get the affect the more out of date the film is. It has also become clear that it is the backing paper casing the mottle. from what I can work out it is the papers expanding and contracting at a different rate to the film base bring into sharp focus how you store the film pointing the finger at big swings in temperature say from fridge to room or freezer to room maybe adding to the increased possibility of it happening.

On further consideration it maybe also be small amounts of moisture caught between the layers causing the large mottle I have experienced over the years along with the film being out of date. The thing that adds to this idea is the insult of the new Foma backing paper having a hole punched in it leaving a circle on the processed negative.Once I have used up all my 120 Foma I may not replace it as I cannot trust it not to ruin a good negatives in the future. Which will be a shame as I like to use it with my pinhole camera.

I should not have to add this to the article the copyright of Mitch Fusco 2022 all rights reserved.

Technical data:

Film I have used that's been affected Ilford FP4+, Fomapan 100, Rollei RPX 400, Agfa 400s.

All images scanned from photographs.

It could have been the backing paper all the time and not the wetting agent.

Wetting agent contamination link